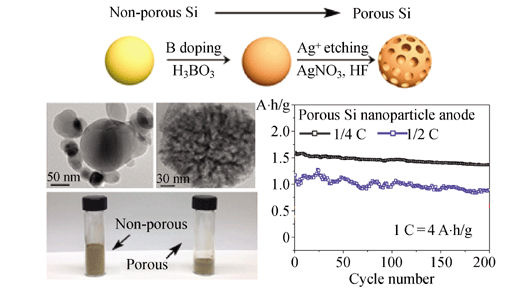

Recent lithium-ion battery research has concentrated on using silicon in battery anodes because it is cheap and has a high potential capacit, but its usefulness was limited as the number of recharge cycles was limited:

The problem has been that previous silicon anode designs, which were basically tiny plates of the material, broke down from repeated swelling and shrinking during charging/discharging cycles and quickly became useless.

Last year Zhou's research team successfully used porous silicon nanowires (100 nanometer in diameter and a few microns lonf) to help overcome this issue:

The tiny pores on the nanowires allowed the silicon to expand and contract without breaking while simultaneously increasing the surface area, which in turn allows lithium ions to diffuse in and out of the battery more quickly, improving performance.

However, nanowires are expensive to manufacture on a large scale, ruling out wide spread commercial adoption. In the latest research Zhou's team used commercially available nanoparticles (silicon spheres) and etched them with the same pores as the nanowires. The researchers note that "the particles function similarly [to the porous nanowire] and can be made in any quantity desired".

The full research paper was published in the January issue of the Nano Research journal (Scalable preparation of porous silicon nanoparticles and their application for lithium-ion battery anodes; Mingyuan Ge, Jiepeng Rong, Xin Fang, Anyi Zhang, Yunhao Lu, Chongwu Zhou).

Image Source: Nano Research