The Tldr; is that yes, this is one possible future for smartphones, but in the short term the physics of making 10 microns-thin sheets of glass is going to be a huge problem for construction and longevity.

But the purpose of this short LOI Flow is to lead you to a well written piece over on The Verge, in which an expert at Schott, one of Samsung's suppliers for this special glass, talks about the issues and compromises involved.

From the story:

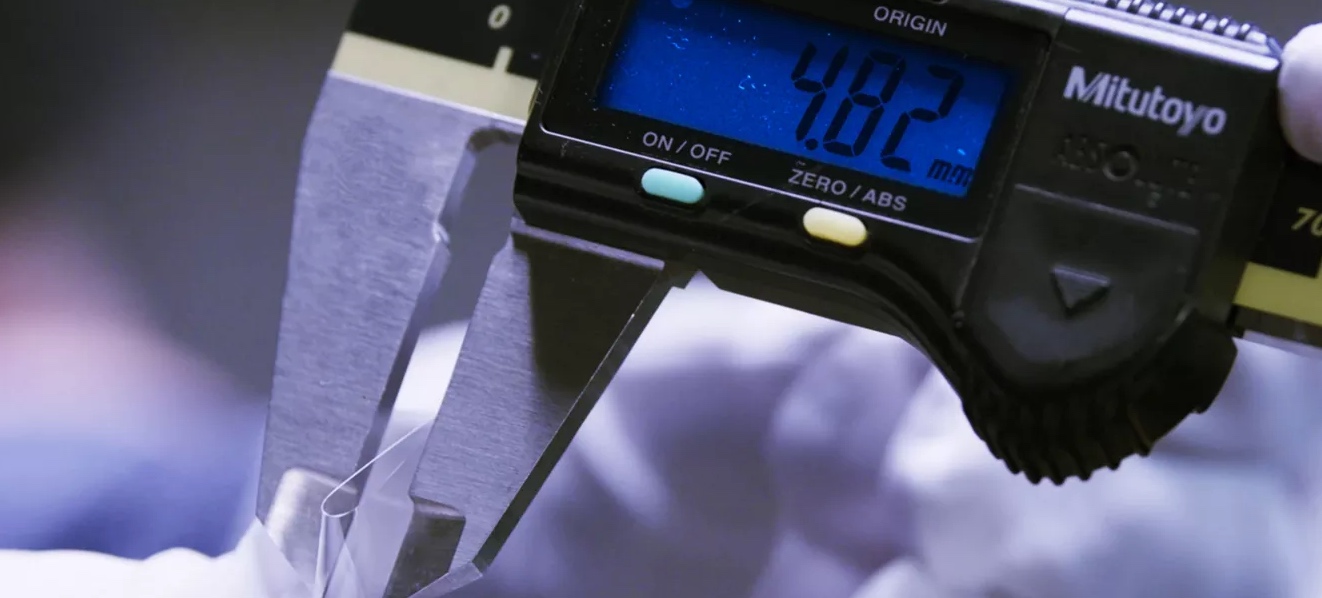

That thinness is already possible with glass that exists today. I touched a 70-micron sheet of Schott glass four years ago, and bent it with my own hands. Samsung says its Z Flip uses a 30-micron-thick glass, and Schott says it’s gone down to 25 microns in the lab as well. Both Corning and Schott use somewhat similar techniques, each creating a floating glass sheet in midair by drawing thin ribbons of molten glass out of specially shaped vats.

But thin isn’t enough by itself. The second “main trick” for bendable glass is to strengthen it against imperfections, particularly at the surface where they can cause catastrophic failures when the glass is stressed. A tiny air bubble, speck of dirt, or minuscule scratch during the manufacturing or handling process might be enough to destroy a piece of bendable glass, experts say. “All the stresses you produce in the glass tend to concentrate on those small defects, and that’s where it will produce a fracture,” says Frankberg.

That’s where chemical baths and heat treatments can come in to strengthen and temper the glass, as we’ve written about before, but the trade-off is that they can make glass easier to scratch. And as your glass gets thinner — thin enough to bend — a scratch becomes even more worrying.

While Mydlak says that a piece of Schott’s glass “can go on forever” in controlled conditions if it survives the first bend test, he admits that one scratch could change that. “If you scratch it with something … this is going to be an initial defect that can cause problems later on,” he says. If a piece of glass with a large enough scratch is bent with enough stress concentrated on a “pre-crack,” says Frankberg, “it will basically propagate with the speed of sound and catastrophically go through the whole material.”

It's a fascinating read, so do follow the link.

It's interesting to muse on the differences between the Z Flip and the Galaxy Fold, that I had lots of hands on time with late last year. It does seem to me that UTG, combined with the form factor, isn't a very good way to head into the future.

| Folding actions during a typical day | Longevity/durability of materials | |

| Galaxy Fold | Perhaps 20, since a lot of the time, quick actions can be done from the cover touchscreen and display | All plastic screen, so vulnerable to dents and cosmetic damage, but the material itself has been tested for hundreds of thousands of 'folds' |

| Galaxy Z Flip | 50 or more, since almost all actions need the device opening up | Ultra-Thin-Glass covered in plastic, so just as vulnerable to dents and cosmetic damage, but with the potential time bomb that any damage at all to the underlying UTG will cause other premature failures/cracks |

Most of all, I think the Surface Duo approach of two separate tough Gorilla Glass 5 screens which work together intelligently is by FAR the best solution. And I can't wait!